Surface Preparation

The process of general galvanizing typically begins with surface preparation. The steel or iron articles are thoroughly cleaned to remove any dirt, grease, or mill scale. This is often done through a combination of chemical cleaning, pickling, and rinsing. Surface preparation is crucial for achieving a strong bond between the zinc coating and the base metal.

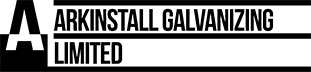

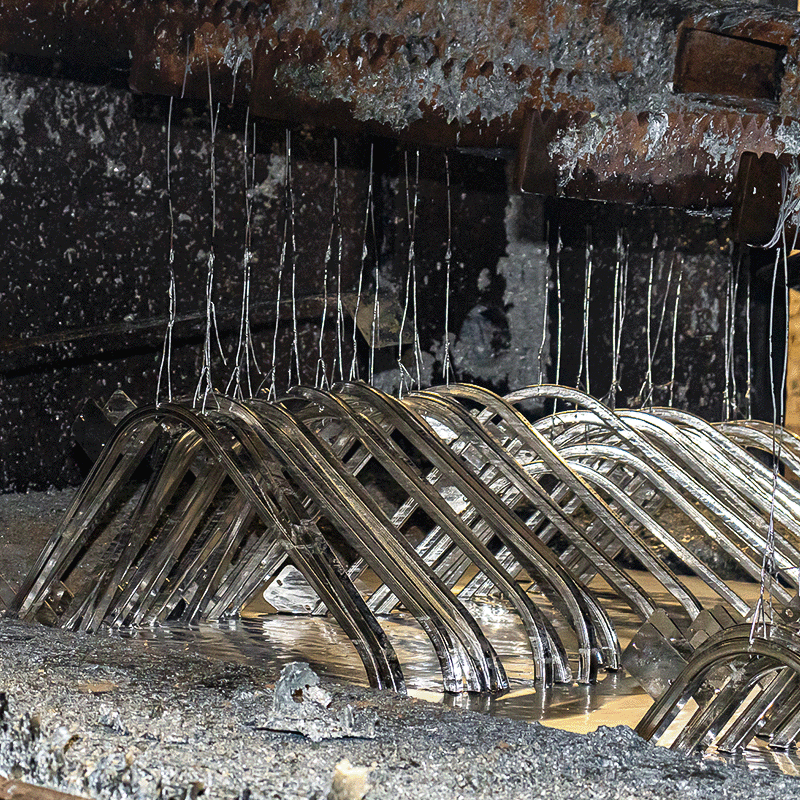

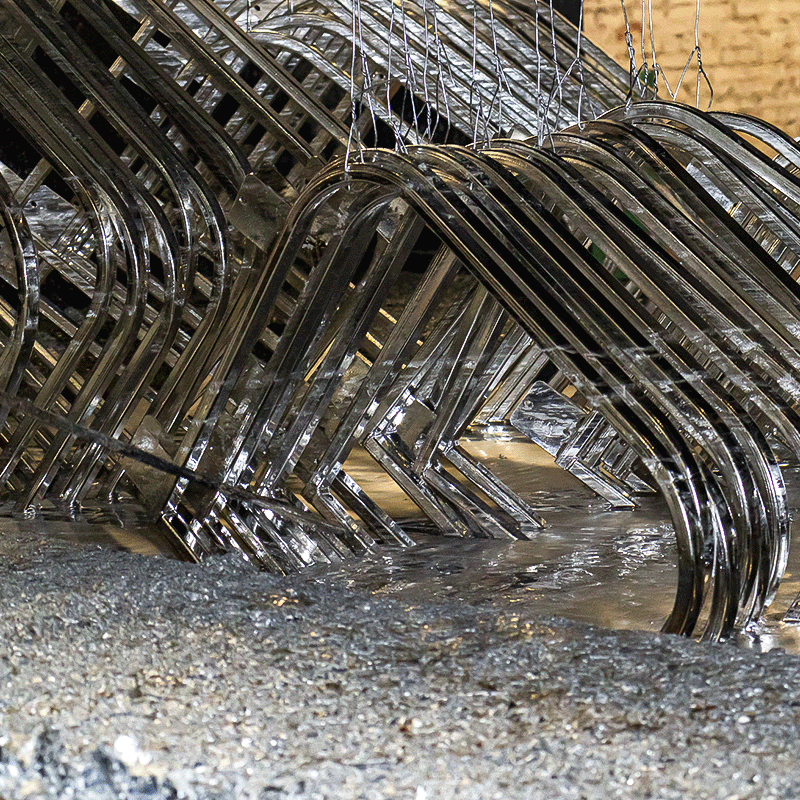

Once the surface is clean, the articles are dipped into a bath of molten zinc at a temperature of around 450 degrees Celsius (850 degrees Fahrenheit). The zinc reacts with the iron or steel to form a series of zinc-iron alloy layers, which provide a barrier against corrosive elements in the environment. The thickness of the galvanized coating can vary depending on the intended application and the thickness of the base metal.

Surface preparation is a crucial step in the general galvanizing process. It involves thorough cleaning of the steel or iron articles to ensure proper adhesion of the zinc coating and enhance the overall quality of the galvanized finish.

Benefits of General Galvanizing

General galvanizing offers a range of benefits that make it an attractive choice for a wide array of applications. First and foremost, galvanized coatings provide exceptional corrosion protection. The zinc acts as a sacrificial anode, corroding preferentially to the underlying steel or iron. This sacrificial action ensures that even if the coating is scratched or damaged, the zinc will continue to protect the metal beneath.

Another advantage of general galvanizing is its long-lasting performance. Galvanized coatings have been known to provide corrosion protection for decades, often exceeding the life expectancy of alternative coating systems. This makes galvanized products a cost-effective choice in the long run, as they require minimal maintenance and replacement.

Furthermore, general galvanizing is a versatile process that can be applied to a wide range of shapes and sizes. From small fasteners and nails to large structural beams and pipes, almost any steel or iron article can be galvanized. This flexibility makes it a popular choice in industries such as construction, automotive, transportation, agriculture, and utilities.

Additionally, galvanized coatings are environmentally friendly. Zinc, the primary component of the coating, is a natural and abundant element. It is fully recyclable, and the recycling process uses less energy compared to the production of new zinc. Furthermore, the durability of galvanized coatings means that they require less frequent replacement, reducing waste generation and environmental impact.

In conclusion, general galvanizing is a highly effective and versatile process for protecting steel and iron against corrosion. Its ability to provide long-lasting protection, its cost-effectiveness, and its environmental benefits make it a preferred choice in various industries. Whether it's for structural applications, outdoor equipment, or everyday products, galvanizing plays a crucial role in extending the lifespan of metals and ensuring their durability in challenging environments.

The Arkinstall Approach

We have built solid partnerships over the many years we have been trading to give us assess to shot blasting, powder coating, larger galvanizing facilities, spin galvanizers and transport companies. Arkinstall have built an enviable reputation for Hot Dip Galvanizing based on more than 120 years experience and as privately owned company, we can offer a highly personalised service tailored to meet your galvanizing requirements.

Arkinstall realise that in today’s competitive environment, companies expect the best possible service from their suppliers. Therefore, we tailor our services to suit the exacting needs of our customers, with over 50% of the goods we produce being processed and dispatched inside of 24 hours.

Birmingham's only

Hot Dip Galvanizer

We have an inhouse capability of up to 4m x 1.7m x 2.4m but can accommodate much larger items that can be processed through our partner facilities.

100+ years industry

Experience

As leading galvanizing experts, we pride ourselves on offering you the highest quality finished products, customer service, help and advice.

Competitive prices and

Turnaround

As the UK's leading hot dip galvanizer, offering a same day or next day service, there is no job too big or too small. Over 75% of our work is in and out within 24 hours